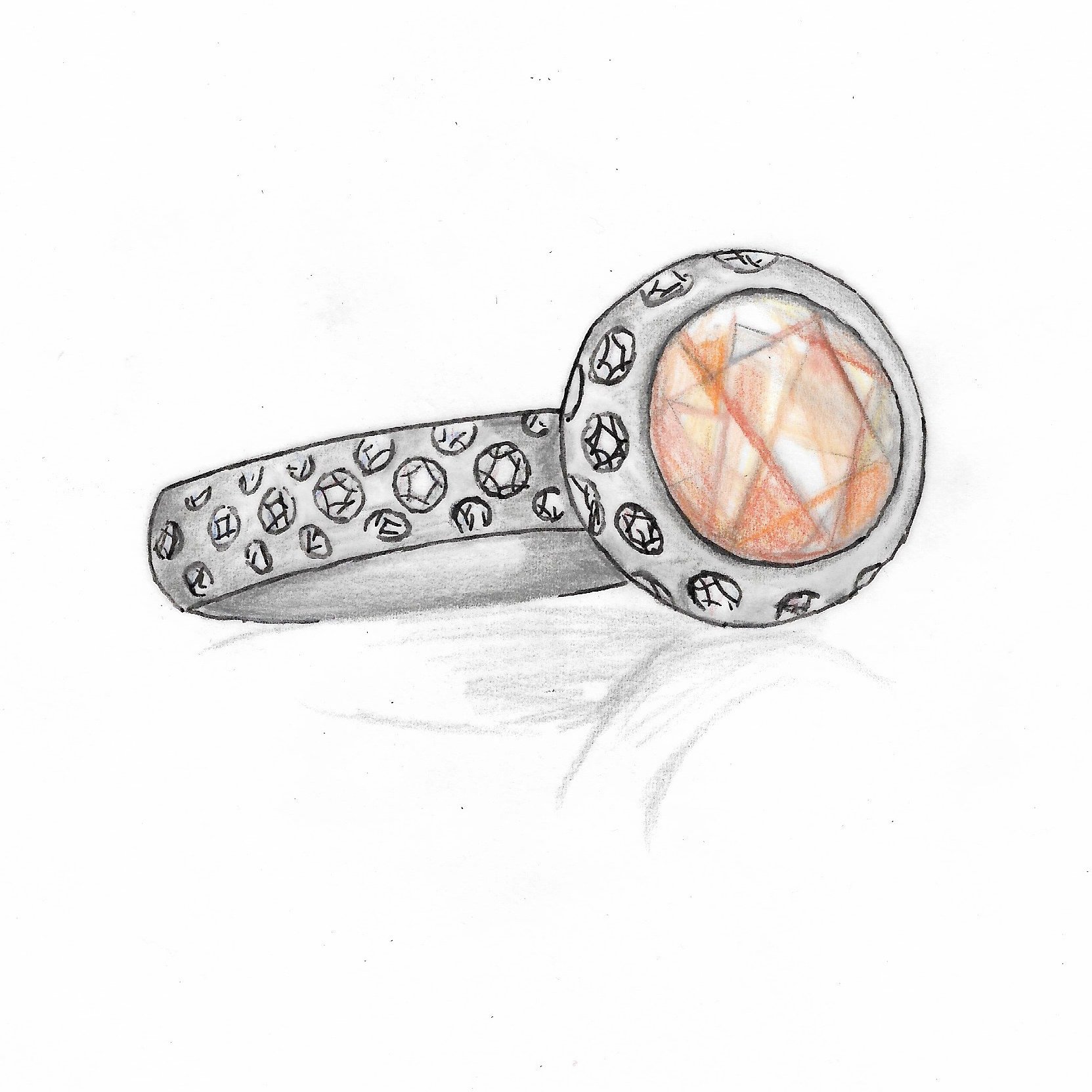

David Ashton

The Process - How to Make a Ring

Here you will discover the process involved in making a diamond set platinum ring.

Every ring is handmade by David using skills he has finely tuned over decades, using tools he has made especially.

This ring is platinum & diamond, many of the processes are the same for gold, and other stones.

1

Firstly we meet or speak to you, we look at examples of David’s work and find out exactly what you are looking for, if required we do a few sketches and once approved we start work.

A lot goes into making one single piece of jewellery

2

Making the band. Draw plates, The plate is held securely in a vice or other fixture. Annealed wire is filed at one end to give it an initial taper. The tapered end is inserted into a hole with a final diameter just smaller than its current diameter. Special pliers called draw tongs hold the tip of the wire & pull it through, with the aid of beeswax as a lubricant.

3

Here are the rolling mills, rolling is a metal forming process in which metal is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform.

4

Before and after milling & drawing. A piece of Platinum 6mm square rod, has been drawn, then milled to produce a piece of 3.3 x 1.9 mm D profile wire, to be made into the shank of a ring, shown here hallmarked.

5

Next David needs to shape the straight piece of metal into a ring, here using half-round pliers and strong hands.

6

Once the ring is round, David welds the ends together with oxyacetylene, the melting temperature of Platinum is 3,224ºF.

7

Now a complete ring, David makes the ring round, and the correct size using a steel mandrill and a hide mallet.

8

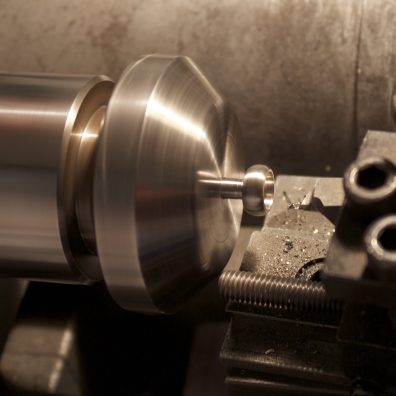

The ring is to have a bulb setting with rub-over and grain set diamonds. A platinum setting is shown here in the lathe.

9

David makes the setting perfectly round and ensures the diamond fits exactly in the setting. Still in the lathe, but turned around, the setting is polished, a post created to locate the setting in the band.

10

The setting is then attached to the band, using oxyacetylene, the metal is at red heat.

11

Next David needs to work out then mark the diamond spacing on the ring using dividers. The ring is coated in a special ink to make the marks easier to see.

12

The ring shank has 79 perfect brilliant cut diamonds set in it, the setting a further 24 plus the main stone. The spacing is worked out and marked in the same way, all to a tolerance of 0.01mm.

13

After marking out, the holes are drilled. Very steady hands are required to ensure the holes are exactly the correct diameter and angle. Yes, the tools are very much like those used by dentists!

14

The main diamond is a rub-over set. David has made his tool, especially for the task. His training as a scientific & medical instrument maker has provided him with excellent skills for such.

15

David sorts fine brilliant cut diamonds into 0.01mm increments, in lines. The small diamonds in the setting have been placed & set, and the middle line in the band is in the process of being set.

16

Small grains of metal hold the diamonds in place. Once all the stones are set, David will spend many hours working with numerous grades of specialist compounds to achieve a perfect mirror-polished finish on the Platinum.